- 電子メール : David@tmaxcn.com

- 電子メール : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

ブログ

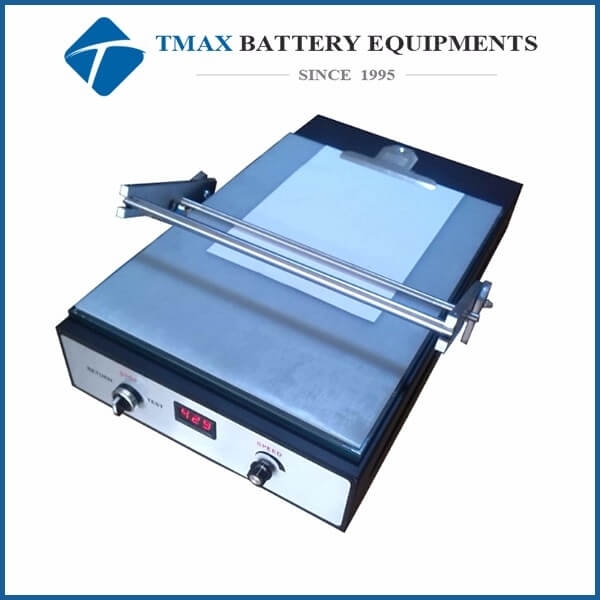

Bar Coater

A bar coater is a device used to apply uniform coatings onto flat substrates, such as glass, plastic films, or metal sheets. It is widely employed in industries like electronics, solar energy, pharmaceuticals, and packaging to create thin, even layers of materials such as paints, adhesives, polymers, and functional coatings. The bar coater's simplicity, precision, and versatility make it an essential tool for both laboratory research and industrial production.

In this article, we will explore the principles, design, applications, advantages, challenges, and innovations associated with bar coaters.

●Principles of Operation

1. Mechanism

A bar coater consists of a precisionengineered coating bar (often made of stainless steel) with grooves or wires on its surface.

The substrate is placed on a flat platform, and a layer of liquid coating material is applied to its surface.

The coating bar is then drawn across the substrate at a controlled speed, leaving behind a uniform layer of the coating material.

2. Key Components

Coating Bar: Determines the thickness and texture of the applied coating. Bars can have different designs, such as wirewound bars or engraved grooves, depending on the desired coating properties.

Substrate Holder: Ensures the substrate remains flat and stable during the coating process.

Coating Reservoir: Holds the liquid material before application.

Speed Control Mechanism: Regulates the speed at which the bar moves across the substrate, affecting coating thickness and uniformity.

●Types of Bar Coaters

1. Manual Bar Coaters

Operated by hand, ideal for smallscale applications or laboratory experiments.

Simple and costeffective but may require more skill to achieve consistent results.

2. Automatic Bar Coaters

Equipped with motorized systems for precise control over speed, pressure, and consistency.

Suitable for largescale production environments where uniformity and repeatability are critical.

3. WireWound Rod Coaters

Use rods with wire wound around them to control coating thickness.

Commonly used in industries requiring precise film thicknesses.

4. Gravure Bar Coaters

Feature engraved patterns on the coating bar to deposit specific amounts of material.

Ideal for creating textured or patterned coatings.

●Advantages of Bar Coaters

1. Precision

Capable of producing highly uniform coatings with minimal variation in thickness.

2. Versatility

Compatible with a wide range of materials, including liquids, pastes, and suspensions.

3. CostEffectiveness

Relatively inexpensive compared to other coating methods, especially for smallscale operations.

4. Ease of Use

Simple setup and operation, making them accessible for both beginners and experienced users.

5. Scalability

Available in various sizes, from labscale models to industrialgrade machines.

●Challenges in Using Bar Coaters

1. Material Compatibility

Some materials may not adhere well to the substrate or may clog the coating bar, requiring adjustments or cleaning.

2. Edge Effects

Coatings may be uneven near the edges of the substrate due to the physical limitations of the bar.

3. Drying and Curing

Proper drying or curing conditions are necessary to ensure the quality of the applied coating.

4. Maintenance

Regular cleaning and calibration of the coating bar are required to maintain performance.

5. Operator Skill

Manual bar coaters demand skill and experience to achieve consistent results.

●Applications of Bar Coaters

Bar coaters are utilized across various industries for diverse applications:

1. Electronics

Applying conductive inks, dielectric materials, and protective coatings to printed circuit boards (PCBs) and flexible electronics.

2. Solar Energy

Depositing photovoltaic materials onto solar panels for efficient energy conversion.

3. Pharmaceuticals

Coating tablets with protective or functional layers to enhance drug stability and delivery.

4. Packaging

Applying adhesives, sealants, and barrier coatings to improve package durability and functionality.

5. Automotive

Creating antiglare, hydrophobic, or decorative coatings on vehicle components.

6. Textiles

Adding waterresistant, flameretardant, or antimicrobial coatings to fabrics.

7. Research and Development

Testing new materials and formulations in laboratory settings.

●Innovations in Bar Coater Technology

To address the challenges and enhance performance, manufacturers are developing advanced bar coater solutions:

1. Smart Coating Systems

Incorporating sensors and realtime monitoring to optimize coating parameters and detect defects.

2. Advanced Materials

Using wearresistant and corrosionresistant materials for longerlasting coating bars.

3. Automation

Integrating robotics and programmable controls for faster and more accurate coating processes.

4. EcoFriendly Solutions

Designing bar coaters that minimize waste and reduce environmental impact.

5. Customizable Designs

Offering tailored solutions for specific materials, substrates, and coating requirements.

●The Future of Bar Coater Technology

As coating demands continue to evolve, so too will the technology behind bar coaters. Key trends shaping the future include:

1. Increased Precision

Development of ultrafine coating bars for nanoscale applications.

2. Focus on Sustainability

Energyefficient designs and ecofriendly materials to minimize environmental impact.

3. Integration with Emerging Technologies

Combining bar coaters with AI, IoT, and cloud computing for smarter diagnostics and analysis.

4. Global Standards Compliance

Ensuring compatibility with evolving international regulations for coating processes.

5. Expansion into New Industries

Adapting bar coaters for emerging fields like biotechnology, aerospace, and quantum computing.

●Conclusion

Bar coaters are a versatile and reliable tool for applying uniform coatings across a wide range of industries. Their ability to produce precise and consistent layers makes them indispensable in modern manufacturing processes.

January 20,2026.

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

Bar Coater: A Key Tool in ThinFilm and Coating Applications

A bar coater is a device used to apply uniform coatings onto flat substrates, such as glass, plastic films, or metal sheets. It is widely employed in industries like electronics, solar energy, pharmaceuticals, and packaging to create thin, even layers of materials such as paints, adhesives, polymers, and functional coatings. The bar coater's simplicity, precision, and versatility make it an essential tool for both laboratory research and industrial production.

In this article, we will explore the principles, design, applications, advantages, challenges, and innovations associated with bar coaters.

●Principles of Operation

1. Mechanism

A bar coater consists of a precisionengineered coating bar (often made of stainless steel) with grooves or wires on its surface.

The substrate is placed on a flat platform, and a layer of liquid coating material is applied to its surface.

The coating bar is then drawn across the substrate at a controlled speed, leaving behind a uniform layer of the coating material.

2. Key Components

Coating Bar: Determines the thickness and texture of the applied coating. Bars can have different designs, such as wirewound bars or engraved grooves, depending on the desired coating properties.

Substrate Holder: Ensures the substrate remains flat and stable during the coating process.

Coating Reservoir: Holds the liquid material before application.

Speed Control Mechanism: Regulates the speed at which the bar moves across the substrate, affecting coating thickness and uniformity.

●Types of Bar Coaters

1. Manual Bar Coaters

Operated by hand, ideal for smallscale applications or laboratory experiments.

Simple and costeffective but may require more skill to achieve consistent results.

2. Automatic Bar Coaters

Equipped with motorized systems for precise control over speed, pressure, and consistency.

Suitable for largescale production environments where uniformity and repeatability are critical.

3. WireWound Rod Coaters

Use rods with wire wound around them to control coating thickness.

Commonly used in industries requiring precise film thicknesses.

4. Gravure Bar Coaters

Feature engraved patterns on the coating bar to deposit specific amounts of material.

Ideal for creating textured or patterned coatings.

●Advantages of Bar Coaters

1. Precision

Capable of producing highly uniform coatings with minimal variation in thickness.

2. Versatility

Compatible with a wide range of materials, including liquids, pastes, and suspensions.

3. CostEffectiveness

Relatively inexpensive compared to other coating methods, especially for smallscale operations.

4. Ease of Use

Simple setup and operation, making them accessible for both beginners and experienced users.

5. Scalability

Available in various sizes, from labscale models to industrialgrade machines.

●Challenges in Using Bar Coaters

1. Material Compatibility

Some materials may not adhere well to the substrate or may clog the coating bar, requiring adjustments or cleaning.

2. Edge Effects

Coatings may be uneven near the edges of the substrate due to the physical limitations of the bar.

3. Drying and Curing

Proper drying or curing conditions are necessary to ensure the quality of the applied coating.

4. Maintenance

Regular cleaning and calibration of the coating bar are required to maintain performance.

5. Operator Skill

Manual bar coaters demand skill and experience to achieve consistent results.

●Applications of Bar Coaters

Bar coaters are utilized across various industries for diverse applications:

1. Electronics

Applying conductive inks, dielectric materials, and protective coatings to printed circuit boards (PCBs) and flexible electronics.

2. Solar Energy

Depositing photovoltaic materials onto solar panels for efficient energy conversion.

3. Pharmaceuticals

Coating tablets with protective or functional layers to enhance drug stability and delivery.

4. Packaging

Applying adhesives, sealants, and barrier coatings to improve package durability and functionality.

5. Automotive

Creating antiglare, hydrophobic, or decorative coatings on vehicle components.

6. Textiles

Adding waterresistant, flameretardant, or antimicrobial coatings to fabrics.

7. Research and Development

Testing new materials and formulations in laboratory settings.

●Innovations in Bar Coater Technology

To address the challenges and enhance performance, manufacturers are developing advanced bar coater solutions:

1. Smart Coating Systems

Incorporating sensors and realtime monitoring to optimize coating parameters and detect defects.

2. Advanced Materials

Using wearresistant and corrosionresistant materials for longerlasting coating bars.

3. Automation

Integrating robotics and programmable controls for faster and more accurate coating processes.

4. EcoFriendly Solutions

Designing bar coaters that minimize waste and reduce environmental impact.

5. Customizable Designs

Offering tailored solutions for specific materials, substrates, and coating requirements.

●The Future of Bar Coater Technology

As coating demands continue to evolve, so too will the technology behind bar coaters. Key trends shaping the future include:

1. Increased Precision

Development of ultrafine coating bars for nanoscale applications.

2. Focus on Sustainability

Energyefficient designs and ecofriendly materials to minimize environmental impact.

3. Integration with Emerging Technologies

Combining bar coaters with AI, IoT, and cloud computing for smarter diagnostics and analysis.

4. Global Standards Compliance

Ensuring compatibility with evolving international regulations for coating processes.

5. Expansion into New Industries

Adapting bar coaters for emerging fields like biotechnology, aerospace, and quantum computing.

●Conclusion

Bar coaters are a versatile and reliable tool for applying uniform coatings across a wide range of industries. Their ability to produce precise and consistent layers makes them indispensable in modern manufacturing processes.

What excites you most about the advancements in bar coater technology? Share your thoughts below! Together, let’s explore how these innovative tools can shape the future of thinfilm and coating applications.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com