- 電子メール : David@tmaxcn.com

- 電子メール : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

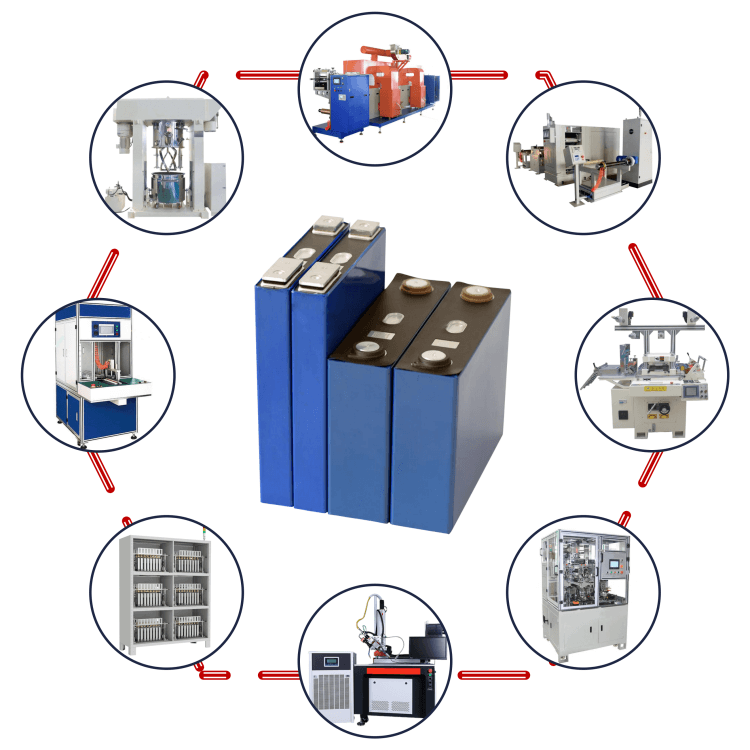

Prismatic battery Pilot line: Advancing Battery Technology at the Development Stage

Introduction:

In the realm of battery technology, prismatic cells have gained significant attention for their high energy density and design versatility. To explore the potential of prismatic cells and optimize their performance, researchers and manufacturers often rely on prismatic cell pilot equipment. This article delves into the significance of prismatic cell pilot equipment, its role in the development stage, and the benefits it brings to the advancement of battery technology.

1.Understanding Prismatic Cells:

Prismatic cells represent a type of rechargeable battery that consists of stacked rectangular layers. These cells offer advantages such as high energy density, enhanced thermal management, and improved packaging efficiency. Prismatic cells have found applications in various industries, including electric vehicles, portable electronics, and energy storage systems.

2.Overview of Prismatic battery production line::

Prismatic cell pilot equipment refers to the specialized machinery and tools used during the development and testing phases of prismatic cells. This equipment facilitates the fabrication of small-scale prismatic cell prototypes, enabling researchers and manufacturers to evaluate different materials, manufacturing processes, and cell designs. It serves as a stepping stone before transitioning to large-scale production.

3.Key Components and Functions:

3.1 Electrode Preparation:

Prismatic cell pilot equipment includes provisions for electrode preparation, which involves coating the electrode materials onto the current collectors. This step ensures uniform electrode thickness, proper adhesion, and optimized electrochemical performance.

3.2 Cell Assembly:

The equipment enables the precise stacking and alignment of electrode layers, separators, and electrolytes. It incorporates mechanisms for controlling pressure, temperature, and the number of layers to achieve consistent and high-quality cell assembly.

3.3 Cell Encapsulation:

Prismatic cell pilot equipment facilitates the encapsulation of assembled cells, ensuring a hermetic seal to prevent electrolyte leakage and external contamination. This step enhances the safety and longevity of the cells during testing and evaluation.

4.Advantages of Prismatic battery manufacturing line:

4.1 Flexibility in Prototyping:

Prismatic cell pilot equipment offers flexibility in the prototyping stage, allowing researchers and manufacturers to explore various cell designs, electrode materials, and manufacturing techniques. This flexibility helps identify the most promising approaches for scaling up production.

4.2 Performance Evaluation:

By using prismatic cell pilot equipment, researchers can assess the performance characteristics of different prismatic cell configurations, electrode compositions, and manufacturing parameters. This evaluation aids in optimizing cell performance, such as capacity, cycle life, power output, and safety.

4.3 Cost and Time Efficiency:

Prismatic cell pilot equipment enables efficient testing and validation, reducing the time and costs associated with full-scale production. The equipment allows for rapid iteration and optimization, accelerating the development cycle and improving time-to-market for advanced battery technologies.

Future Trends and Outlook:

As the demand for high-performance batteries continues to grow, the role of prismatic cell pilot equipment is expected to expand further. Technological advancements in the equipment's automation, precision, and scalability will drive innovation in prismatic cell designs, materials, and manufacturing processes. This will contribute to the development of more efficient, durable, and cost-effective prismatic cell technologies.

Conclusion:

Prismatic cell pilot equipment plays a vital role in advancing battery technology by enabling efficient prototyping, evaluation, and optimization of prismatic cells. By providing flexibility, performance evaluation capabilities, and cost efficiency, this equipment accelerates the development of high-performance prismatic cells. As the battery industry progresses, further advancements in prismatic cell pilot equipment will facilitate the realization of next-generation energy storage solutions.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com