- 電子メール : David@tmaxcn.com

- 電子メール : Davidtmaxcn@gmail.com

- : No. 39, Xinchang Road, Xinyang, Haicang Dist., Xiamen, Fujian, China (Mainland)

ブログ

Car Battery Manufacturing

April 11,2025.

Car Battery Manufacturing: The Backbone of Automotive Power

Car battery manufacturing is a critical process that ensures vehicles have reliable power

sources for starting engines, powering electronics, and supporting hybrid or electric

propulsion systems. As the automotive industry evolves toward electrification and advanced

technologies, the demand for high-performance car batteries continues to grow. In this

blog post, we’ll explore the key aspects of car battery manufacturing, including its

processes, types of batteries, challenges, and future trends.

---

●What Is Car Battery Manufacturing?

Car battery manufacturing involves designing, producing, and assembling batteries

specifically tailored for automotive applications. These batteries provide electrical

energy for essential functions such as engine ignition, lighting, infotainment systems,

and, in the case of electric vehicles (EVs), propulsion. The manufacturing process

combines advanced materials, precise engineering, and rigorous quality control to deliver

durable, safe, and efficient batteries.

---

●Types of Car Batteries

Different types of car batteries are manufactured based on their intended use:

1. Lead-Acid Batteries

- Description: Traditional car batteries used primarily for starting, lighting, and

ignition (SLI) in conventional internal combustion engine (ICE) vehicles.

- Key Features:

- Cost-effective and widely available.

- Reliable performance under various conditions.

- Recyclable, with a well-established recycling infrastructure.

- Applications: ICE vehicles, marine, and industrial equipment.

2. Lithium-Ion Batteries

- Description: High-energy-density batteries commonly used in hybrid electric vehicles

(HEVs) and fully electric vehicles (EVs).

- Key Features:

- Lightweight and compact.

- Long cycle life and high efficiency.

- Suitable for high-power applications.

- Applications: EVs, HEVs, plug-in hybrids, and energy storage systems.

3. Nickel-Metal Hydride (NiMH) Batteries

- Description: An older technology still used in some hybrid vehicles.

- Key Features:

- Higher energy density than lead-acid but lower than lithium-ion.

- Durable and resistant to extreme temperatures.

- Applications: Older-generation HEVs.

4. Solid-State Batteries (Emerging Technology)

- Description: Next-generation batteries with solid electrolytes instead of liquid

ones.

- Key Features:

- Improved safety due to reduced risk of thermal runaway.

- Higher energy density and longer lifespan.

- Applications: Future EVs and high-performance applications.

---

●Car Battery Manufacturing Process

The manufacturing process varies depending on the type of battery but generally includes

the following stages:

1. Material Preparation

- Raw materials such as lead, lithium compounds, nickel, cobalt, manganese, and

graphite are sourced and processed.

- Electrolytes, separators, and other components are prepared for assembly.

2. Electrode Production

- For lithium-ion batteries, cathode and anode materials are mixed with binders and

solvents to create slurries.

- The slurries are coated onto metal foils (aluminum for cathodes, copper for anodes)

and dried to form electrodes.

3. Cell Assembly

- Electrodes and separators are stacked or wound together to form individual cells.

- Cells are enclosed in cases (prismatic, cylindrical, or pouch formats).

4. Electrolyte Injection

- Electrolyte is injected into the cells to enable ion movement between electrodes.

5. Formation and Activation

- Cells undergo a formation process where they are charged and discharged under

controlled conditions to activate their electrochemical properties.

6. Module and Pack Assembly

- Qualified cells are grouped into modules and assembled into complete battery packs.

- Wiring, cooling systems, and protective housings are integrated.

7. Testing and Quality Control

- Batteries are rigorously tested for capacity, internal resistance, leakage, safety,

and durability.

- Defective units are discarded, while qualified units proceed to packaging and

shipping.

---

●Challenges in Car Battery Manufacturing

Despite advancements, car battery manufacturing faces several challenges:

1. Supply Chain Constraints:

- Securing raw materials like lithium, cobalt, and nickel is becoming increasingly

difficult due to geopolitical tensions, environmental concerns, and rising demand.

2. Cost Management:

- Reducing production costs while maintaining quality is essential for mass-market

adoption, especially in EVs.

3. Safety and Reliability:

- Ensuring batteries are safe from thermal runaway, fires, or explosions requires

stringent testing and design improvements.

4. Environmental Impact:

- Extracting raw materials and disposing of spent batteries pose significant

environmental challenges.

5. Technological Advancements:

- Keeping up with rapid innovations in battery chemistry, such as solid-state and

sodium-ion technologies, demands continuous investment in R&D.

---

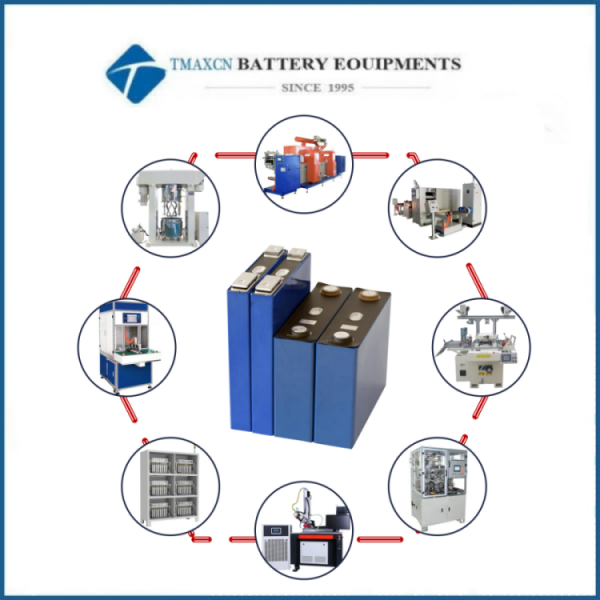

Power battery prodcution line

●Innovations in Car Battery Manufacturing

To address these challenges and improve efficiency, manufacturers are adopting cutting-

edge technologies:

1. Automation and Robotics:

- Advanced robotics and automation reduce labor costs, increase precision, and enhance

throughput.

2. AI and Machine Learning:

- AI-driven analytics optimize production processes, predict failures, and improve

yield rates.

3. Sustainable Practices:

- Recycling programs and closed-loop systems recover valuable materials from spent

batteries, reducing waste and conserving resources.

4. Next-Generation Chemistries:

- Research into new battery chemistries, such as lithium-sulfur, sodium-ion, and

solid-state batteries, promises higher energy densities, lower costs, and improved safety.

---

●The Role of Car Battery Manufacturing in Shaping the Future

As the world transitions toward cleaner energy sources and electrified transportation, car

battery manufacturing will play a pivotal role in driving this transformation. It enables:

1. Decarbonization:

- By providing efficient energy storage solutions, car batteries support the

integration of renewable energy into the grid and the adoption of zero-emission vehicles.

2. Energy Independence:

- Localized battery production reduces reliance on imported fossil fuels and

strengthens national energy security.

3. Job Creation:

- The growth of car battery manufacturing creates high-skilled jobs in engineering,

manufacturing, and research.

---

●Conclusion

Car battery manufacturing is at the heart of modern automotive innovation. From powering

traditional ICE vehicles to enabling the transition to electric mobility, these batteries

are indispensable in building a cleaner, more connected future. As technology advances and

sustainability becomes a priority, the industry will continue to evolve, offering exciting

opportunities for growth and improvement.

What excites you most about the future of car battery manufacturing? Share your thoughts

in the comments below! Together, let’s explore how innovation in battery production can

Car battery manufacturing is a critical process that ensures vehicles have reliable power

sources for starting engines, powering electronics, and supporting hybrid or electric

propulsion systems. As the automotive industry evolves toward electrification and advanced

technologies, the demand for high-performance car batteries continues to grow. In this

blog post, we’ll explore the key aspects of car battery manufacturing, including its

processes, types of batteries, challenges, and future trends.

---

●What Is Car Battery Manufacturing?

Car battery manufacturing involves designing, producing, and assembling batteries

specifically tailored for automotive applications. These batteries provide electrical

energy for essential functions such as engine ignition, lighting, infotainment systems,

and, in the case of electric vehicles (EVs), propulsion. The manufacturing process

combines advanced materials, precise engineering, and rigorous quality control to deliver

durable, safe, and efficient batteries.

---

●Types of Car Batteries

Different types of car batteries are manufactured based on their intended use:

1. Lead-Acid Batteries

- Description: Traditional car batteries used primarily for starting, lighting, and

ignition (SLI) in conventional internal combustion engine (ICE) vehicles.

- Key Features:

- Cost-effective and widely available.

- Reliable performance under various conditions.

- Recyclable, with a well-established recycling infrastructure.

- Applications: ICE vehicles, marine, and industrial equipment.

2. Lithium-Ion Batteries

- Description: High-energy-density batteries commonly used in hybrid electric vehicles

(HEVs) and fully electric vehicles (EVs).

- Key Features:

- Lightweight and compact.

- Long cycle life and high efficiency.

- Suitable for high-power applications.

- Applications: EVs, HEVs, plug-in hybrids, and energy storage systems.

3. Nickel-Metal Hydride (NiMH) Batteries

- Description: An older technology still used in some hybrid vehicles.

- Key Features:

- Higher energy density than lead-acid but lower than lithium-ion.

- Durable and resistant to extreme temperatures.

- Applications: Older-generation HEVs.

4. Solid-State Batteries (Emerging Technology)

- Description: Next-generation batteries with solid electrolytes instead of liquid

ones.

- Key Features:

- Improved safety due to reduced risk of thermal runaway.

- Higher energy density and longer lifespan.

- Applications: Future EVs and high-performance applications.

---

●Car Battery Manufacturing Process

The manufacturing process varies depending on the type of battery but generally includes

the following stages:

1. Material Preparation

- Raw materials such as lead, lithium compounds, nickel, cobalt, manganese, and

graphite are sourced and processed.

- Electrolytes, separators, and other components are prepared for assembly.

2. Electrode Production

- For lithium-ion batteries, cathode and anode materials are mixed with binders and

solvents to create slurries.

- The slurries are coated onto metal foils (aluminum for cathodes, copper for anodes)

and dried to form electrodes.

3. Cell Assembly

- Electrodes and separators are stacked or wound together to form individual cells.

- Cells are enclosed in cases (prismatic, cylindrical, or pouch formats).

4. Electrolyte Injection

- Electrolyte is injected into the cells to enable ion movement between electrodes.

5. Formation and Activation

- Cells undergo a formation process where they are charged and discharged under

controlled conditions to activate their electrochemical properties.

6. Module and Pack Assembly

- Qualified cells are grouped into modules and assembled into complete battery packs.

- Wiring, cooling systems, and protective housings are integrated.

7. Testing and Quality Control

- Batteries are rigorously tested for capacity, internal resistance, leakage, safety,

and durability.

- Defective units are discarded, while qualified units proceed to packaging and

shipping.

---

●Challenges in Car Battery Manufacturing

Despite advancements, car battery manufacturing faces several challenges:

1. Supply Chain Constraints:

- Securing raw materials like lithium, cobalt, and nickel is becoming increasingly

difficult due to geopolitical tensions, environmental concerns, and rising demand.

2. Cost Management:

- Reducing production costs while maintaining quality is essential for mass-market

adoption, especially in EVs.

3. Safety and Reliability:

- Ensuring batteries are safe from thermal runaway, fires, or explosions requires

stringent testing and design improvements.

4. Environmental Impact:

- Extracting raw materials and disposing of spent batteries pose significant

environmental challenges.

5. Technological Advancements:

- Keeping up with rapid innovations in battery chemistry, such as solid-state and

sodium-ion technologies, demands continuous investment in R&D.

---

Power battery prodcution line

●Innovations in Car Battery Manufacturing

To address these challenges and improve efficiency, manufacturers are adopting cutting-

edge technologies:

1. Automation and Robotics:

- Advanced robotics and automation reduce labor costs, increase precision, and enhance

throughput.

2. AI and Machine Learning:

- AI-driven analytics optimize production processes, predict failures, and improve

yield rates.

3. Sustainable Practices:

- Recycling programs and closed-loop systems recover valuable materials from spent

batteries, reducing waste and conserving resources.

4. Next-Generation Chemistries:

- Research into new battery chemistries, such as lithium-sulfur, sodium-ion, and

solid-state batteries, promises higher energy densities, lower costs, and improved safety.

---

●The Role of Car Battery Manufacturing in Shaping the Future

As the world transitions toward cleaner energy sources and electrified transportation, car

battery manufacturing will play a pivotal role in driving this transformation. It enables:

1. Decarbonization:

- By providing efficient energy storage solutions, car batteries support the

integration of renewable energy into the grid and the adoption of zero-emission vehicles.

2. Energy Independence:

- Localized battery production reduces reliance on imported fossil fuels and

strengthens national energy security.

3. Job Creation:

- The growth of car battery manufacturing creates high-skilled jobs in engineering,

manufacturing, and research.

---

●Conclusion

Car battery manufacturing is at the heart of modern automotive innovation. From powering

traditional ICE vehicles to enabling the transition to electric mobility, these batteries

are indispensable in building a cleaner, more connected future. As technology advances and

sustainability becomes a priority, the industry will continue to evolve, offering exciting

opportunities for growth and improvement.

What excites you most about the future of car battery manufacturing? Share your thoughts

in the comments below! Together, let’s explore how innovation in battery production can

shape a brighter tomorrow.

English▼

English▼

+86 13174506016

+86 13174506016 David@tmaxcn.com

David@tmaxcn.com